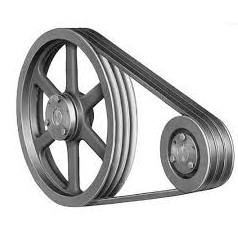

From high power belt drives in quarries, critical pumps in chemical processing plants, to precise control in scientific equipment Fenner Transmission Belt Drives continue to provide exceptional service. Built using the highest quality materials, with technically advanced production processes, and backed with rigorous quality procedures, Fenner belts, pulleys and Taper Lock® shaft fixings together form the complete belt drive solution.

Classical V-Belts

Ideal for high ratio or small pulley drives, the PRMS Classic V belt has a specially treated jacket to give superior anti-static, heat and oil resistant properties which exceeds the new industry anti-ignition standards.

- Accuracy and stability of length

- Complete range of lengths and sections

- 'One Shot' tensioning for fit-and-forget reliability

- Extended temperature range -40°C to +70°C

- PB® (Precision Build) Technology, eliminating the need for matching

- Fully approved by all international standards

- BS 3790 (British Standard)

- ISO 4184 (International Standards Organisation)

- RMA IP20

- DIN 2215 (German Institute for Standardisation)

- Static conductive in accordance with ISO 1813

- Conforms to American Petroleum Institute specifications

Ultra PLUS

Designed for use in single or multi-belt drives, PRMS Ultra PLUS transmission belts deliver maximum cost and performance benefits by utilising low elongation polyester cords and abrasion resistant impregnated jacket fabric.

- Ideal for use in single or multi-belt drives

- 'One Shot' tensioning for fit-and-forget reliability

- Extended temperature range -55°C to +70°C

- PB® (Precision Build) Technology, eliminating the need for matching

- Meets highest industry standards for static conductivity and non-ignition properties.

- Conditionally oil resistant

- Complete range of lengths and sections

- Fully approved by all international standards

- BS 3790 (British Standard)

- ISO 4184 (International Standards Organisation)

- RMA IP22 (Rubber Manufacturers Association)

- DIN 7753 (German Institute for Standardisation)

- Electrically conductive in accordance with ISO 1813

- Conforms to American Petroleum Institute specifications

Ultra PLUS CRE

The PRMS Ultra PLUS CRE belt is ideal for use in high ratio applications often required by today's compact drive envelopes. Combining flexibility with structural stability, it offers higher running efficiency than wrapped belts.

- Special compounds improve flexibility and strength

- Higher running efficiency than wrapped belts

- Run cooler than wrapped belts

- Extended temperature range -30°C to +70°C

- PB® (Precision Build) Technology, eliminating the need for matching

- Conditionally oil resistant

- Fully approved by all international standards

- BS 3790 (British Standard)

- ISO 4184 (International Standards Organisation)

- DIN 7753 (German Institute for Standardisation)

- Static conductive in accordance with ISO 1813

- Conforms to American Petroleum Institute specifications

Quattro PLUS Twin Wrapped Wedge Belt

The PRMS Quattro PLUS TW is a wrapped belt that has been specifically designed with a 2-ply outer jacket to reduce belt elongation and improve stability. Suitable for a wide range of industries and uses, this maintenance free belt transmits 30% more power than traditional wrapped belts.

- State-of-the-art wrapped chloroprene rubber construction

- Higher modulus polyester cord reduces belt elongation

- 2-ply outer jacket improves belt length stability and improves abrasion resistance

- Suitable for counterbending/back-tensioners

- Suitable for clutches

- Extended temperature range -30°C to +80°C

- PB® (Precision Build) Technology, eliminating the need for matching

- Conditionally oil resistant

- Fully approved by all international standards

- BS 3790 (British Standard)

- ISO 4184 (International Standards Organisation)

- DIN 7753 (German Institute for Standardisation)

- Electrically conductive to ISO 1813

- Conforms to American Petroleum Institute specifications

Quattro PLUS CRE

The PRMS Quattro PLUS CRE is a step forward in belt technology. It's high performance unique polyester tension member and EPDM contact section allows it to transmit 26% more power than our traditional CRE range and offers up to 15% longer service life.

- Synthetic rubber EPDM heavy duty wedge belt

- Embedding compound for stable power transfer

- Enhanced tooth profile improves belt flexibility, reducing bending resistance and increasing efficiency and life

- Unique construction of the polyester tension member improves accuracy and stability of belt length

- Reduced belt weight lowers inertia and reduces vibration allowing smoother running

- Lower pre-tensioning force allows longer bearing life and extends maintenance periods between re-tensioning

- Abrasion resistant compound for enhanced durability

- Extended temperature range -40°C to +130°C

- PB® (Precision Build) Technology, eliminating the need for matching

- Conditionally oil resistant

- Fully approved by all international standards

- BS 3790 (British Standard)

- ISO 4184 (International Standards Organisation)

- DIN 7753 (German Institute for Standardisation)

- Electrically conductive to ISO 1813

- Conforms to American Petroleum Institute specifications

Concord PLUS Banded Belt

The advantages of Fenner wedge belts are combined with a neoprene/fabric band to form a single belt. Ideal for applications where pulsating or shock loads cause instability in matched sets of wedge or V belts, Fenner Concord PLUS banded belts can provide the ideal solution by providing sufficient lateral rigidity to eliminate such problems.

- Eliminates belt whip, belt twist and belt turn over

- Ideal for drives with pulsating loads

- Heat and oil resistant

- Supplied to suit either Fenner® ISO standard Taper Lock® pulleys or RMA standard pulleys

- Fully approved by all international standards

- BS 3790 (British Standard)

PolyDrive PLUS Ribbed Belts

Fenner PolyDrive PLUS ribbed belts are an ideal solution for compact drives in household appliances and heavy machinery. The ribbed belts enable economic solutions even under difficult drive conditions, such as large transmission ratios, high belt speeds, small pulley diameters and back idler pulleys.

- High belt speeds up to 60m/s (belt speeds above 40m/s require special pulley materials)

- Designed for high transmission ratios

- High power output

- Low vibration, efficient belt

- Long service life

- Available in PJ, PK, PL & PM profiles

- Fully approved by all international standards

Geometry of each section complies to ISO 9982

Static conductive to ISO 1813

PowerTwist PLUS Link Belting

The state-of-the-art solution for emergency replacement and fitment into inaccessible locations. PowerTwist PLUS belts are manufactured from high strength urethane/polyester composite, ensuring the finished product is incredibly strong, yet flexible enough to work in the roughest of conditions.

- Made to any length in seconds

- Available in standard (Z, A, B, C), and double sections (AA, BB etc)

- Highly resistant to heat, water, oil, chemicals etc.

- Use with Fenner® ISO standard Taper Lock® pulleys, optionally with RMA pulleys

- Easy to install, rivet-less construction, no tools necessary

- Standard or optional soft back, for conveying applications

Classical Timing Belt

PRMS Classical Timing Belts are the original square toothed belts. In conjunction with their associated pulleys classical belts provide an economic solution for light drive applications.

- Classical profile imperial pitch belts

- Wide range of belts and Taper Lock® pulleys

- Efficient and economical

- Fully approved by all international standards

- ISO 5296 (International Standards Organisation)

- BS 4548 (British Standard)

HTD Timing Belt

PRMS HTD timing belts are the first generation of metric curvilinear tooth form synchronous belts for high torque drives. With their associated Taper Lock® Pulleys, they form cost effective drives for medium duty applications.

- Curvilinear tooth improves stress distribution for higher tooth strength

- Offers a more compact drive than classical timing belt drives

- Full range of Taper Lock® pulleys in 5, 8 and 14mm pitch

- Fully approved by all international standards

- ISO 13050 (International Standards Organisation)

Torque Drive PLUS 3

The state-of-the-art Fenner Torque Drive PLUS 3 (TDP3) works with standard HTD pulleys to provide the ultimate combination of power capacity, low noise and high accuracy in a belt drive. Manufactured using the latest materials and production technology, Fenner Torque Drive PLUS 3 continues to push the boundaries of belt engineering

- The highest power rating for rubber/glassfibre belts

- Enhanced compounding and glassfibre cord excel in highly dynamic applications

- Minimum backlash for precise positioning

- Ultra compact and cost effective drives

- Polyamide facing layer reduces noise and belt tooth wear

- Runs optimally on standard HTD pulleys

- Fully approved by all international standards

- ISO 13050 (International Standards Organisation)

Friction Pulleys

PRMS friction pulleys are manufactured from high grade iron (GG25), tolerate shock loading and achieve rim speeds of up to 40m/s. Available with pilot bore fixings or using the Taper Lock® shaft fixing system for ultimate versatility, Fenner friction pulleys provide a high grade of accuracy.

- Incorporate universal dual duty design grooves (ISO 4183) and accept both V and wedge belts

- Statically balanced to exceed grade G 6.3 (ISO 1940)

- Rim speeds up to a maximum of 40m/s

- Blackened to reduce corrosion, acts as an ideal primer and removes the need for cleaning coating agents prior to installation.

- Consistent and high grade of accuracy e.g. groove wobble tolerance exceeds DIN 2211 part 1 requirements

- Taper Lock® mounting, for quick and simple installation

- Special designs and sizes available

Synchronous Pulleys

PRMS synchronous pulleys are manufactured from high grade iron (GG25), tolerate shock loading and achieve rim speeds of up to 40m/s. Available with pilot bore fixings or using the Taper Lock® shaft fixing system for ultimate versatility.

- Available in both classical Timing and HTD profiles

- Statically balanced to exceed grade G 6.3 (ISO 1940)

- Rim speeds up to a maximum of 40m/s

- Blackened to reduce corrosion, acts as an ideal primer and removes the need for cleaning coating agents prior to installation.

- Precision machined grooves to protect and maximise belt life whilst reducing noise

- Taper Lock® mounting, for quick and simple installation

- Special designs and sizes available